An interview by Evi Mibelli with Auro Po, President of Steel Cucine.

“Steel is a noble material, it has something eternal in it. This is why our company is called Steel – steel – to make products that, like steel, survive ourselves” – Auro Po, President of Steel Cucine.

There is a beginning, a pioneer and a project. A project that changes over time through four generations of entrepreneurs. The common thread for everyone is courage, love for steel and cooking. It was 1922. A young Angelo Po, a blacksmith, begins producing stoves not only for heating but also for cooking and drying laundry. A beautiful intuition, because it gives life to a multifunctional product ahead of its time.

Oxford line by Steel Cucine.

Success was not long in coming and his small company, in Carpi, expanded and grew, transforming from artisanal to industrial: it produces in series and specializes in the construction of professional kitchens for catering. It became a point of reference in the sector and accumulated, over time, an invaluable wealth of skills which, even today, constitutes the treasure from which to draw to project ourselves into the future. The path, however, is never linear. It knows setbacks, difficulties and challenges that can rightly be defined as survival.

Ascot line by Steel Cucine.

This is the story that Auro Po, President of Steel Cucine, decided to share. A reality that owes its strength and determination to the values handed down from generation to generation and which have little to do with the cold logic of marketing and finance. It takes more, much more to be unique. They are called heart, passion, emotion, competence, coherence.

Steel Cucine was born in 1999, carrying with it the historical legacy of the family business. Until 2009 it worked, above all, as an important subcontractor for the main global household appliance brands, a basin that ensures enormous volumes but reduced margins, due to the pricing policies applied by the leaders of the sector. A very useful observatory for knowing the industrial and commercial policies of large groups from the inside.

Auro Po, President of Steel Cucine.

In 2010 the objectives changed: the idea was to transfer the technology and knowledge gained in the production of professional kitchens into the world of the home. It is a change of pace, an opening towards a world made of colours, lifestyles, projects. It means rethinking production while maintaining a very clear and stable link with the professional performance of catering kitchens but changed, through the search for beauty, in the daily life of those seeking maximum efficiency and design.

“One of our characteristics is observing what happens around us. We had noticed a strong interest, at trade fairs and meetings, in our professional kitchens from people who did not work in the catering world. They were attracted by the quality of the materials, the performance of use, functionality and safety. But certainly not for the design. It was like wanting to buy an SUV and finding yourself with a super-tractor with zero appeal. Hence the idea of opening up to a market that aspired to professional performance and features in the kitchen, but with a refined design in details and finishes”

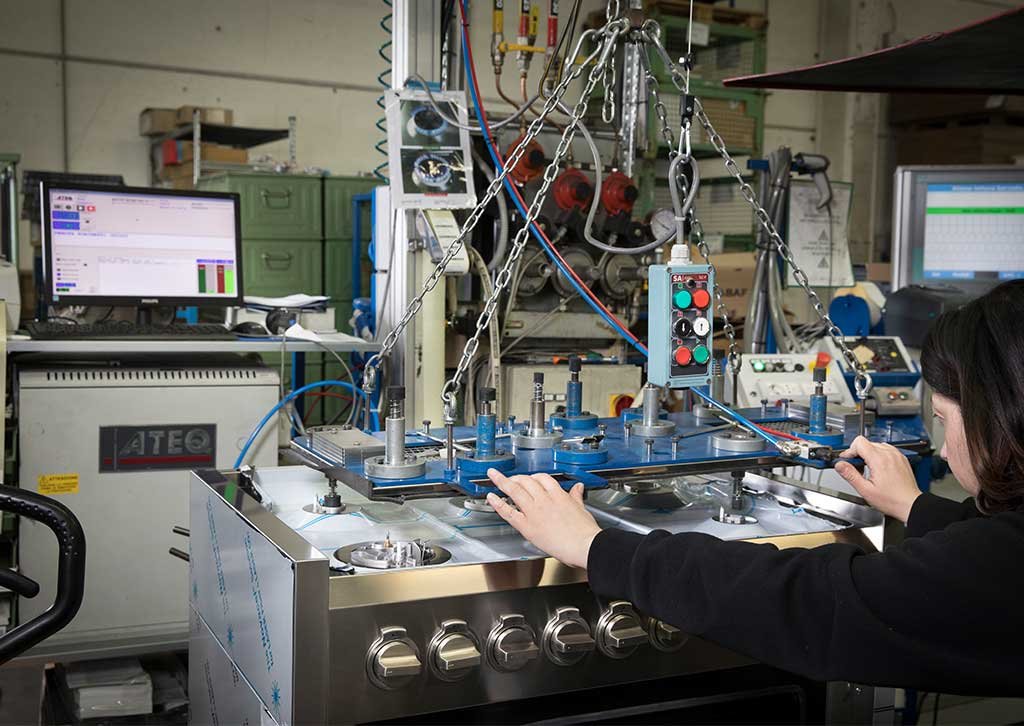

A detail of the production within the company.

A winning intuition! But as with all ideas, the real challenge was turning it into reality. “We knew we would be penalized in terms of costs. Our product costs much more than those commonly on the market, precisely as a function of the technical and technological choices. Process and product costs have an important impact, but we were unable and, above all, did not want to give up that technical heritage that has characterized us in the professional world. Certain solutions cannot be obtained with standard appliance technology, because the latter is designed for the production of large numbers. And for us competing with Electrolux, Bosch, Whirlpool made no sense. We would have lost from the start”

“We aimed at a niche market, to promote and enhance our brand. There is no point in hiding how, faced with a change of objective, we also found ourselves needing to enter a sales network that was completely new to us. For this reason we have signed a series of collaborations with important specialized groups, through which we have reached the market of our interest and learned about its distribution dynamics.”

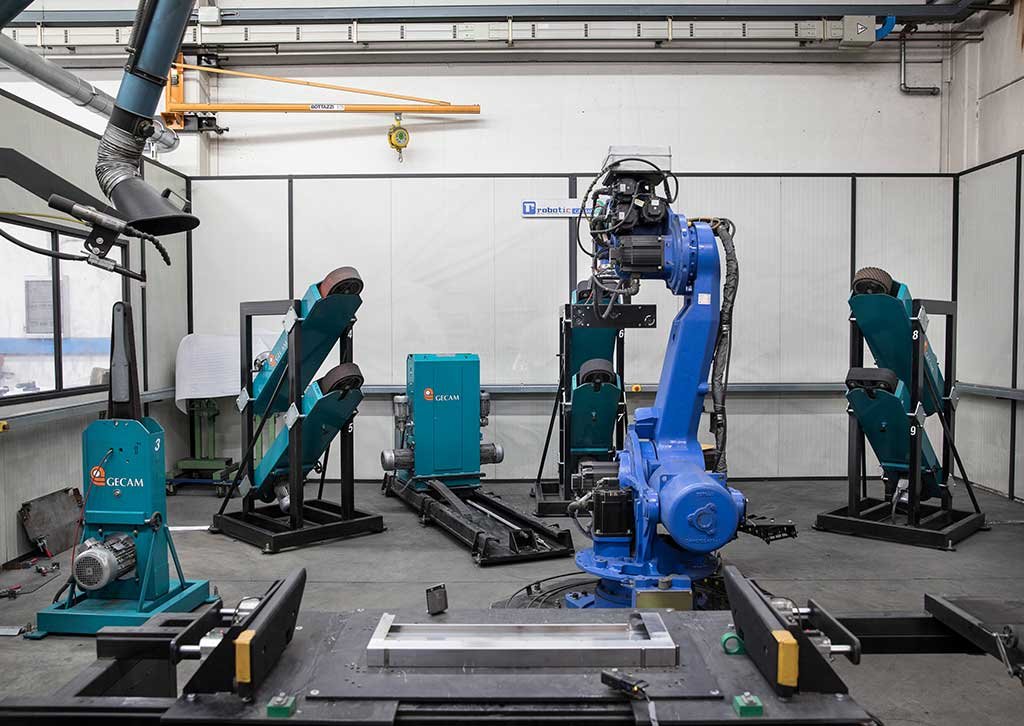

Various machinery used during the processing phases.

The watershed was the 2009 crisis, following the Lehmann Brothers scandal. The market suffers a collapse, large customers impose drastic cuts in investments with repercussions on the entire household appliance industry.

“In February 2010 our turnover was zero. In February 2010 our turnover was zero. We started again, as already mentioned, focusing exclusively on our brand. We have rebuilt a product, a technical assistance network, redesigned the industrial and organizational structure. This choice did not reward us immediately but already in the second year we had achieved a turnover that was 50% of that achieved the year before the great crisis. With one difference: more significant and advantageous margins than in the past thanks to distribution by brand. For us, the crisis was a real driver of change”

There is an aspect that is often not talked about when faced with choices that determine the future of a company: the importance of people.

“Our structure is rooted in the principles of ‘familiarity’. There is a cohesion that does not end in strictly parental bonds. Our employees are key partners for success. They are often children of those who worked for our fathers in the past. This has meant that a bond has been created that goes beyond the simple relationship between entrepreneur and worker. It is an asset that cannot be quantified in profit. It is worth infinitely more.”

“Machines can be efficient and facilitate production but those who make them work are people. When we found ourselves in the midst of the crisis in 2010, everyone was informed and involved in the conversion journey. There are those who, close to retirement, have anticipated their exit and those who have decided to share the risk and stay. Today’s success is not just thanks to us, it must be shared with everyone”

There is no lack of manual touch in the details of a production proudly made in Italy.

The choice to position itself in a selected niche of the market also suggests a critically constructive approach to the topic of sustainability. Steel products are created, in fact, with the precise desire to last a very long time, well beyond, for example, the logic of the planned obsolescence household appliance of the great leaders.

“Talking about environmental sustainability and continuing to fuel – behind the mantra of energy efficiency – the logic of consumption with ‘timed’ scrapping is questionable to say the least and raises more than one question. That said, the topic is central for us and affects the entire corporate ecosystem. We have a closed production cycle where each step is designed to produce the lowest waste from steel processing, waste which is recovered and sent to the steelworks to be transformed back into raw material”.

“Similarly, the packaging issue: the material used is 85% recycled and recyclable. Our machines are low consumption, as are our products which are designed to reduce cooking times with consequent energy savings. Finally, all our products undergo aging simulation tests. The result? They pass the scrutiny of multiple generations. And what is more sustainable than a product that does not lose efficiency, quality or reliability over time?”

Identity, respect for one’s roots, no subjection to the large concentrations of the global market, foresight, coherence, entrepreneurial courage… Steel Cucine is all this and much more: it is proudly made in Italy.

Gea Marmolada outdoor kitchen by Steel Cucine.

On the cover, Enfasi line by Steel Cucine.